Knowledge related to Profibus communication protocol

1.Basic structure of Profibus communication protocol

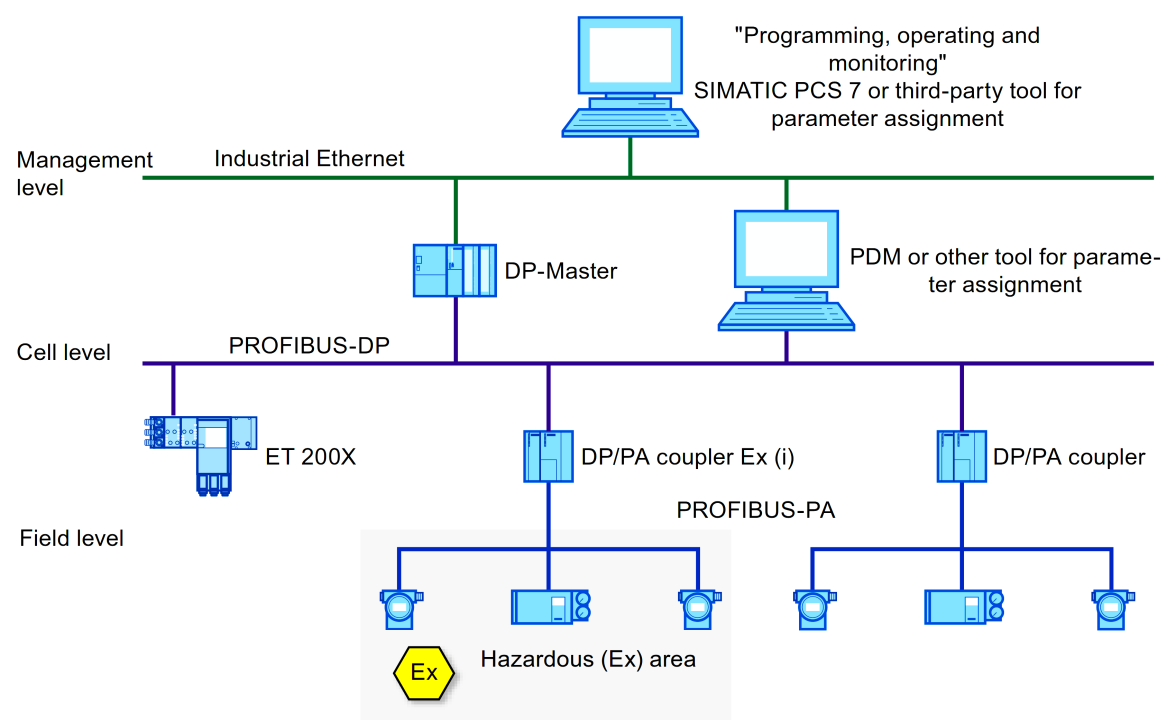

Profibus (Process Field Bus) communication protocol is a communication standard used in the field of industrial automation. It is designed to achieve reliable and real-time data communication between field devices (such as sensors, actuators, etc.) and control devices in the automation system. This protocol provides a standardized way to enable devices produced by different manufacturers to communicate on the same network, enabling data exchange and control command transmission between devices.

The infrastructure of Profibus mainly includes the following key elements:

Master station and slave station: The Profibus network consists of a master station (Master) and multiple slave stations (Slave). The master station is responsible for controlling the communication process, issuing commands to the slave stations, and collecting responses from the slave stations. The slave station executes the instructions issued by the master station and transmits real-time data and status information to the master station. This master-slave structure makes the Profibus system have the characteristics of distributed control and real-time performance.

Physical layer: Profibus can adopt different physical layer standards, including RS-485, optical fiber, etc. The physical layer determines the electrical characteristics of data transmission, such as transmission rate, communication distance and anti-interference ability. RS-485 is one of the commonly used physical layer standards, supports long-distance communication, and has strong anti-interference performance.

Data transmission method: Profibus uses serial communication to transmit data bit by bit and frame by frame. Data transmission can be periodic, for real-time data transmission, or event-triggered, for handling specific events, such as fault alarms. This data transmission method enables the Profibus system to adapt to different application scenarios.

Data frame structure: The data frame is the basic unit of Profibus communication, including the frame header, data field, and frame tail. The frame header is used to identify the beginning of the frame, the data field stores the actual data information, and the frame tail marks the end of the frame. The structure of the data frame can be configured according to communication needs, making it more flexible.

2. Working principle of Profibus communication protocol

The working principle of the Profibus communication protocol involves data exchange between the master station and the slave station, communication cycle, data frame composition, error detection and correction, etc. The following is the basic working principle of the Profibus communication protocol:

Interaction between master and slave:

Master: The master is responsible for controlling the entire Profibus network. It periodically polls all slaves, sends command requests or data queries to the slaves, and receives responses from the slaves.

Slave: The slave station executes the commands issued by the master station and transmits real-time data and status information to the master station. The slave interacts with the master by responding when it is polled.

Communication cycle:

The Profibus communication protocol adopts a periodic communication method, in which the master station polls each slave station at predetermined intervals. This periodic communication ensures real-time performance, allowing the system to respond to control commands and obtain real-time data quickly.

The composition of the data frame:

Profibus communication takes place via data frames. Each data frame contains a frame header, data field, and frame trailer.

Frame header: used to identify the beginning of the data frame.

Data Domain: Contains actual data information, which can be control commands, real-time data, etc.

End of frame: Marks the end of the data frame.

Data transmission method:

Data transmission is carried out bit by bit and frame by frame, using serial communication. This method ensures efficient data transmission and is suitable for long-distance communications in industrial environments.

Error detection and correction:

The Profibus communication protocol has built-in error detection and correction mechanisms to ensure communication reliability. Mechanisms including parity check, CRC (cyclic redundancy check), etc. are used to detect and correct errors during transmission.

Communication speed and performance:

Profibus supports different communication rates and can be configured according to system requirements. The choice of communication rate affects the speed of data transmission. Choose the appropriate communication rate according to the application's requirements to ensure performance.

The infrastructure of the Profibus communication protocol provides a solid foundation for industrial automation. Through the organizational structure of the master station and the slave station, as well as the use of serial communication and flexible data frame structure, the Profibus system can achieve efficient and reliable data transmission and equipment control.