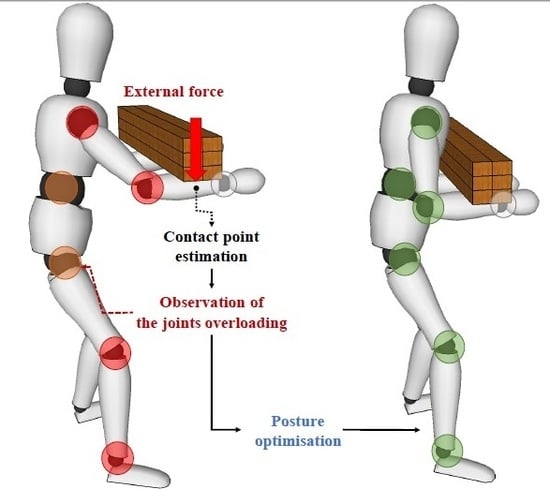

An Online Method to Detect and Locate an External Load on the Human Body with Applications in Ergonomics Assessment

Abstract

:1. Introduction

2. Contact Point Detection and Localisation

2.1. Estimation of the Contact Point Position

| Algorithm 1 Detection of contact point position. |

|

2.2. Whole-Body Centre of Pressure Model

3. Overloading Joint Torque

4. Experimental Analysis

4.1. Experimental Setup

4.2. Results

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| CoP | centre of pressure |

| CoM | centre of mass |

| DoFs | degrees of freedom |

| EAWS | ergonomic assessment work-sheet |

| EMG | electromyography |

| ERC | european reasearch council |

| IMU | inter-connected inertial238measurement unit |

| SESC | statically equivalent serial chain |

| vGRF | vertical ground reaction force |

References

- Vanderborght, B. Unlocking the Potential of Industrial Human-Robot Collaboration; Technical Report; Publications Office of the European Union: Brussels, Belgium, 2019. [Google Scholar]

- Westgaard, R. Work-related musculoskeletal complaints: Some ergonomics challenges upon the start of a new century. Appl. Ergon. 2000, 31, 569–580. [Google Scholar] [CrossRef]

- Jovic, J.; Escande, A.; Ayusawa, K.; Yoshida, E.; Kheddar, A.; Venture, G. Humanoid and human inertia parameter identification using hierarchical optimization. IEEE Trans. Robot. 2016, 32, 726–735. [Google Scholar] [CrossRef]

- Millard, M.; Uchida, T.; Seth, A.; Delp, S.L. Flexing computational muscle: Modeling and simulation of musculotendon dynamics. J. Biomech. Eng. 2013, 135, 021005. [Google Scholar] [CrossRef] [PubMed]

- Bonnet, V.; Venture, G. Fast determination of the planar body segment inertial parameters using affordable sensors. IEEE Trans. Neural Syst. Rehabil. Eng. 2015, 23, 628–635. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Yu, Y.; Zhou, Y.; Li, Y.; Du, S. Measuring accurate body parameters of dressed humans with large-scale motion using a Kinect sensor. Sensors 2013, 13, 11362–11384. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Luca, A.; Albu-Schaffer, A.; Haddadin, S.; Hirzinger, G. Collision detection and safe reaction with the DLR-III lightweight manipulator arm. In Proceedings of the 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 9–15 October 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 1623–1630. [Google Scholar]

- De Luca, A.; Flacco, F. Integrated control for pHRI: Collision avoidance, detection, reaction and collaboration. In Proceedings of the 2012 4th IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 288–295. [Google Scholar]

- Ji, Z.; Zhu, H.; Liu, H.; Liu, N.; Chen, T.; Yang, Z.; Sun, L. The design and characterization of a flexible tactile sensing array for robot skin. Sensors 2016, 16, 2001. [Google Scholar] [CrossRef] [PubMed]

- Makihata, M.; Muroyama, M.; Tanaka, S.; Nakayama, T.; Nonomura, Y.; Esashi, M. Design and fabrication technology of low profile tactile sensor with digital interface for whole body robot skin. Sensors 2018, 18, 2374. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pham, T.H.; Caron, S.; Kheddar, A. Multicontact interaction force sensing from whole-body motion capture. IEEE Trans. Ind. Inform. 2017, 14, 2343–2352. [Google Scholar] [CrossRef]

- Brubaker, M.A.; Sigal, L.; Fleet, D.J. Estimating contact dynamics. In Proceedings of the 2009 IEEE 12th International Conference on Computer Vision, Kyoto, Japan, 29 September–2 October 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 2389–2396. [Google Scholar]

- Pham, T.H.; Kheddar, A.; Qammaz, A.; Argyros, A.A. Towards force sensing from vision: Observing hand-object interactions to infer manipulation forces. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA, 7–12 June 2015; pp. 2810–2819. [Google Scholar]

- Murai, A.; Kurosaki, K.; Yamane, K.; Nakamura, Y. Musculoskeletal-see-through mirror: Computational modeling and algorithm for whole-body muscle activity visualization in real time. Prog. Biophys. Mol. Biol. 2010, 103, 310–317. [Google Scholar] [CrossRef] [PubMed]

- De Luca, C.J.; Gilmore, L.D.; Kuznetsov, M.; Roy, S.H. Filtering the surface EMG signal: Movement artifact and baseline noise contamination. J. Biomech. 2010, 43, 1573–1579. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.; Lee, J.; Tsagarakis, N.; Ajoudani, A. A real-time and reduced-complexity approach to the detection and monitoring of static joint overloading in humans. In Proceedings of the 2017 International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 828–834. [Google Scholar]

- González, A.; Hayashibe, M.; Bonnet, V.; Fraisse, P. Whole body center of mass estimation with portable sensors: Using the statically equivalent serial chain and a kinect. Sensors 2014, 14, 16955–16971. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Winter, D.A. Human balance and posture control during standing and walking. Gait Posture 1995, 3, 193–214. [Google Scholar] [CrossRef]

- Ziegler, J.; Kretzschmar, H.; Stachniss, C.; Grisetti, G.; Burgard, W. Accurate human motion capture in large areas by combining IMU-and laser-based people tracking. In Proceedings of the 2011 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Francisco, CA, USA, 25–30 September 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 86–91. [Google Scholar]

- Kok, M.; Hol, J.D.; Schön, T.B. Using inertial sensors for position and orientation estimation. arXiv 2017, arXiv:1704.06053. [Google Scholar]

- Wang, J.M.; Fleet, D.J.; Hertzmann, A. Gaussian process dynamical models for human motion. IEEE Trans. Pattern Anal. Mach. Intell. 2007, 30, 283–298. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johnson, N.L.; Kotz, S.; Balakrishnan, N. Continuous Univariate Distributions; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 1995. [Google Scholar]

- Gao, G. Statistical modeling of SAR images: A survey. Sensors 2010, 10, 775–795. [Google Scholar] [CrossRef] [PubMed]

- Anderson, T.W.; Darling, D.A. A test of goodness of fit. J. Am. Stat. Assoc. 1954, 49, 765–769. [Google Scholar] [CrossRef]

- Stephens, M.A. EDF statistics for goodness of fit and some comparisons. J. Am. Stat. Assoc. 1974, 69, 730–737. [Google Scholar] [CrossRef]

- Easton, V.J.; McCollś, J.H. Statistics Glossary v1.1. Available online: http://www.stats.gla.ac.uk/steps/glossary/ (accessed on 19 February 2020).

- Ci, B. Confidence intervals. Lancet 1987, 1, 494–497. [Google Scholar]

- Hyon, S.H. Compliant terrain adaptation for biped humanoids without measuring ground surface and contact forces. IEEE Trans. Robot. 2009, 25, 171–178. [Google Scholar] [CrossRef]

- Jeong, H.; Yamada, K.; Kido, M.; Okada, S.; Nomura, T.; Ohno, Y. Analysis of Difference in Center-of-Pressure Positions between Experts and Novices during Asymmetric Lifting. IEEE J. Transl. Eng. Health Med. 2016, 4, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Lorenzini, M.; Kim, W.; De Momi, E.; Ajoudani, A. A Real-time Graphic Interface for the Monitoring of the Human Joint Overloadings with Application to Assistive Exoskeletons. In Proceedings of the International Symposium on Wearable Robotics, Pisa, Italy, 16–20 October 2018; Springer: Berlin, Germany, 2018; pp. 281–285. [Google Scholar]

| [m] | ||

|---|---|---|

| 0.735 | 1.96 | 0.01 |

| Subject | Experimental Condition | Percentage Error | Estimation Time |

|---|---|---|---|

| Hands | 1.022% | 9.4 s | |

| 1 | Mid-forearms | 20.92% | 16.1 s |

| Mid-upper arms | 11.15% | 14.4 s | |

| Hands | 1.17% | 16.0 s | |

| 2 | Mid-forearms | 48.04% | 27.2 s |

| Mid-upper arms | 16.05% | 17.5 s |

| Overloading Level | Control Threshold |

|---|---|

| GREEN | |

| ORANGE | |

| RED |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lorenzini, M.; Kim, W.; De Momi, E.; Ajoudani, A. An Online Method to Detect and Locate an External Load on the Human Body with Applications in Ergonomics Assessment. Sensors 2020, 20, 4471. https://doi.org/10.3390/s20164471

Lorenzini M, Kim W, De Momi E, Ajoudani A. An Online Method to Detect and Locate an External Load on the Human Body with Applications in Ergonomics Assessment. Sensors. 2020; 20(16):4471. https://doi.org/10.3390/s20164471

Chicago/Turabian StyleLorenzini, Marta, Wansoo Kim, Elena De Momi, and Arash Ajoudani. 2020. "An Online Method to Detect and Locate an External Load on the Human Body with Applications in Ergonomics Assessment" Sensors 20, no. 16: 4471. https://doi.org/10.3390/s20164471