Components of a refrigeration system (VCRS) and its functions in ship

A refrigeration system consists of several components that work together to remove heat from a space or substance and maintain a lower temperature. These components play specific roles in the refrigeration cycle.

Components of Refrigeration system:

- Compressor

- Condenser

- Drier

- Thermostatic expansion valve.

- Evaporator.

- Sensing bulb

Compressor:

Compressor is used for compressing the refrigerant gas in the refrigerant system. A single-acting or double-acting compressor is commonly used for compressing and supplying refrigerant in the line with pressure. It is fitted after the evaporator in the refrigeration line.

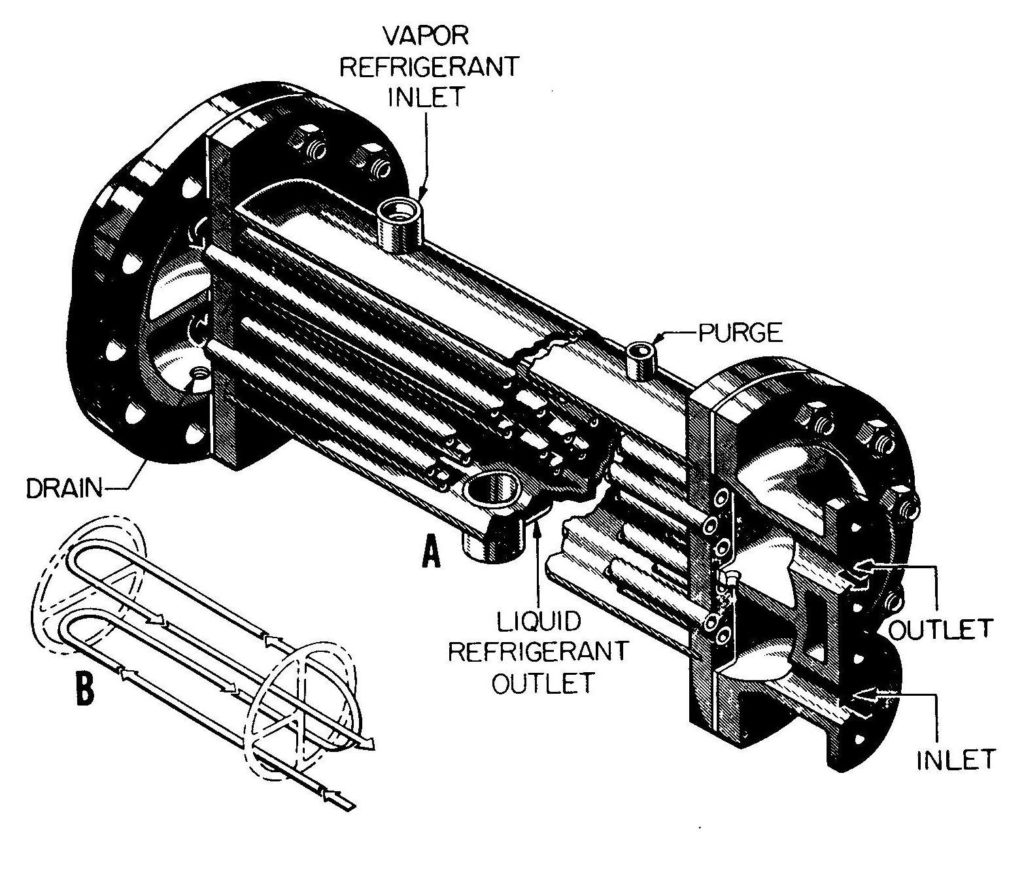

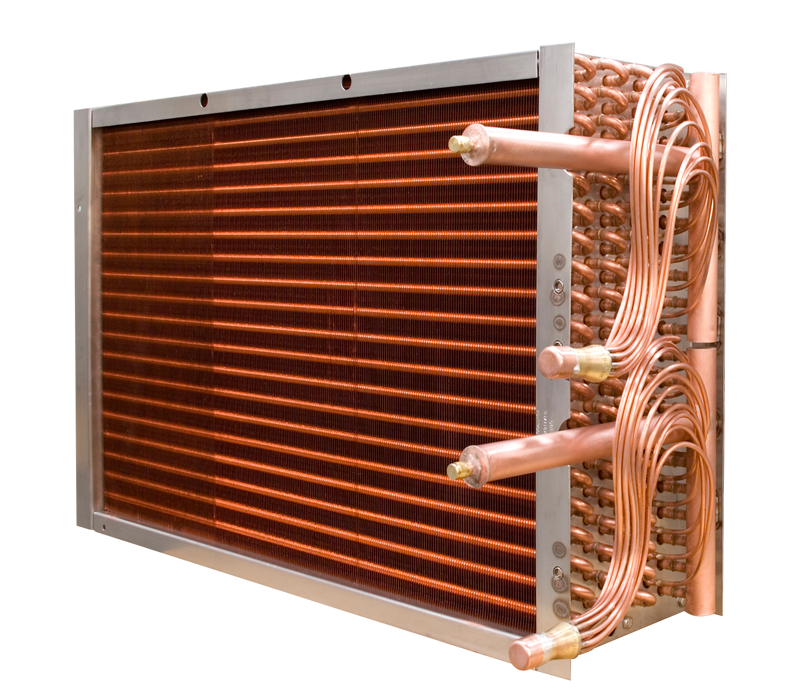

Condenser:

Condenser is a device which reduces the temperature of refrigerant gas and converts it into liquid form. Refrigerant gas after passing through the compressor has high temp. Inside the condenser, the refrigerant exchanges heat with the help of a seawater circulation and converts the vapour into liquid. It is fitted between the compressor and dryer.

Drier:

The dryer has silica gel in it which absorbs the moisture present in the refrigerant.

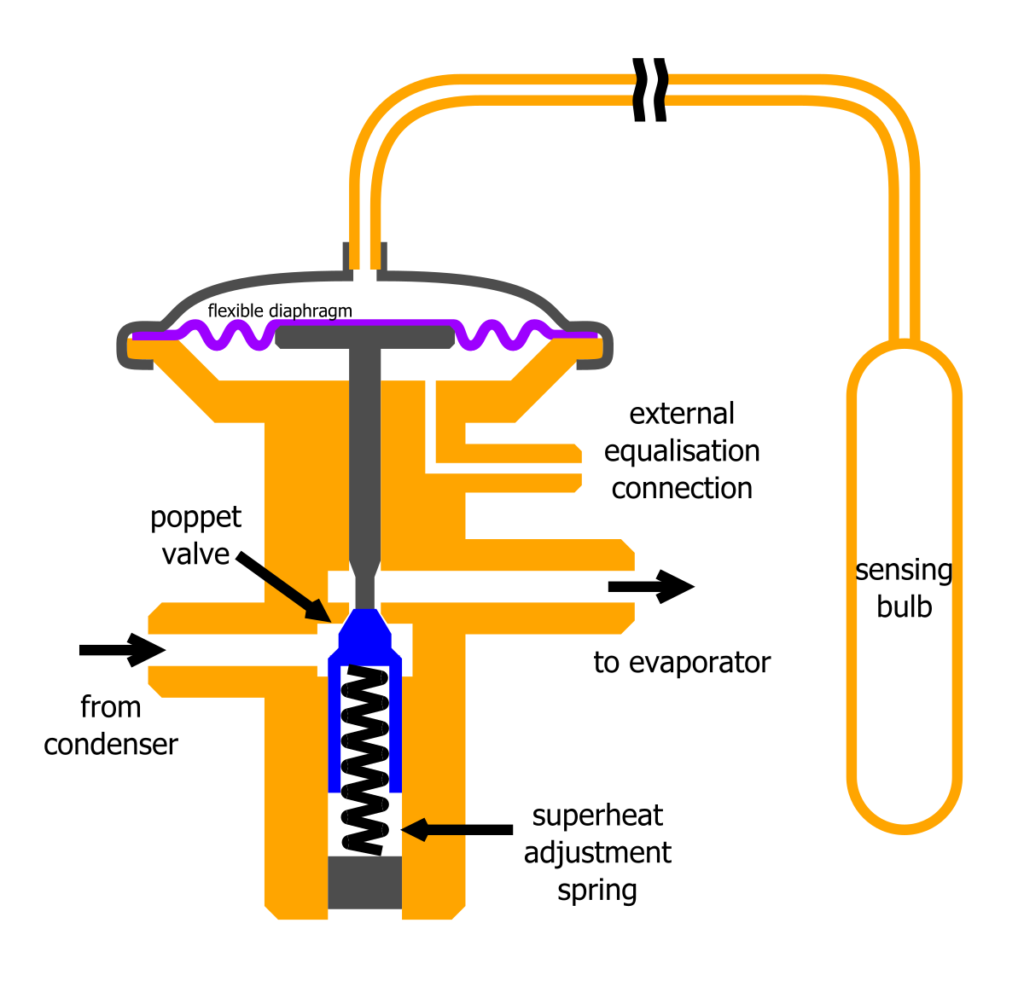

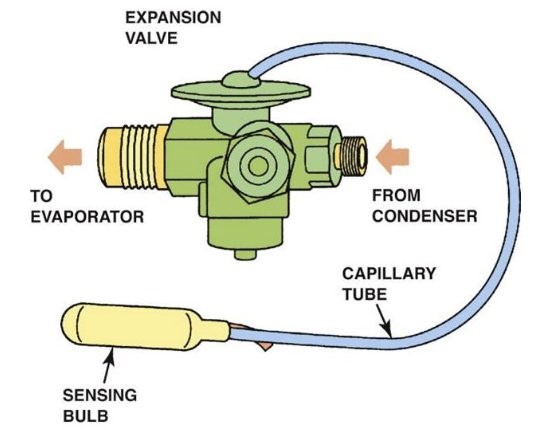

Thermostatic expansion valve:

The thermostatic expansion valve is used for regulating the flow of refrigerant into the evaporator. The high-pressure refrigerant passes through an orifice after which it expands which leads to a sudden decrease in pressure and temperature. This valve is connected to the sensing bulb to regulate the flow of liquid through the expansion valve.

Evaporator:

It acts like a heat exchanger, where it takes the heat from the area of refrigeration, exchanges it with the refrigerant and converts it into vapour form. This continuous process cools down the area of refrigeration.

Sensing bulb:

The bulb is fastened to the outside of the evaporator outlet so that temperature changes in the refrigerant leaving the evaporator are sensed by the expansion or contraction of the fluid. Ideally, the gas should leave with 6–7 degrees of superheat. This ensures that the refrigerant is being used efficiently and that no liquid reaches the compressor. A starved condition in the evaporator will result in a greater superheat through which the liquid will expand in the bulb and capillary causing the valve to open further and increase the flow of refrigerant. The sensing bulb is connected to a TEV with a capillary tube.

Note:

If you want to learn more about this topic, we suggest checking out our Combo package with the given link https://www.merchantnavydecoded.com/courses/c/ . It’s a great way to dive deeper into the subject through video explanations. This package covers all the important details and presents them in an easy-to-understand format. Watching the videos will help you grasp the topic better and make learning more enjoyable. So, we highly recommend giving our Combo package a try to enhance your knowledge on the subject.

Disclaimer :- The opinions expressed in this article belong solely to the author and may not necessarily reflect those of Merchant Navy Decoded. We cannot guarantee the accuracy of the information provided and disclaim any responsibility for it. Data and visuals used are sourced from publicly available information and may not be authenticated by any regulatory body. Reviews and comments appearing on our blogs represent the opinions of individuals and do not necessarily reflect the views of Merchant Navy Decoded. We are not responsible for any loss or damage resulting from reliance on these reviews or comments.

Reproduction, copying, sharing, or use of the article or images in any form is strictly prohibited without prior permission from both the author and Merchant Navy Decoded.