Maker: Jim Wilde, professor of civil engineering, Minnesota State University, Mankato

Every year the American Society of Civil Engineers holds a national competition that challenges college students to build a concrete canoe. It has to float, obviously, and that rule remains even if the canoe breaks in two. Wilde has led student-entry efforts at MSU for the last three decades. This is the most basic form of construction: a hand-molded craft in which concrete is applied to a simple hull form.

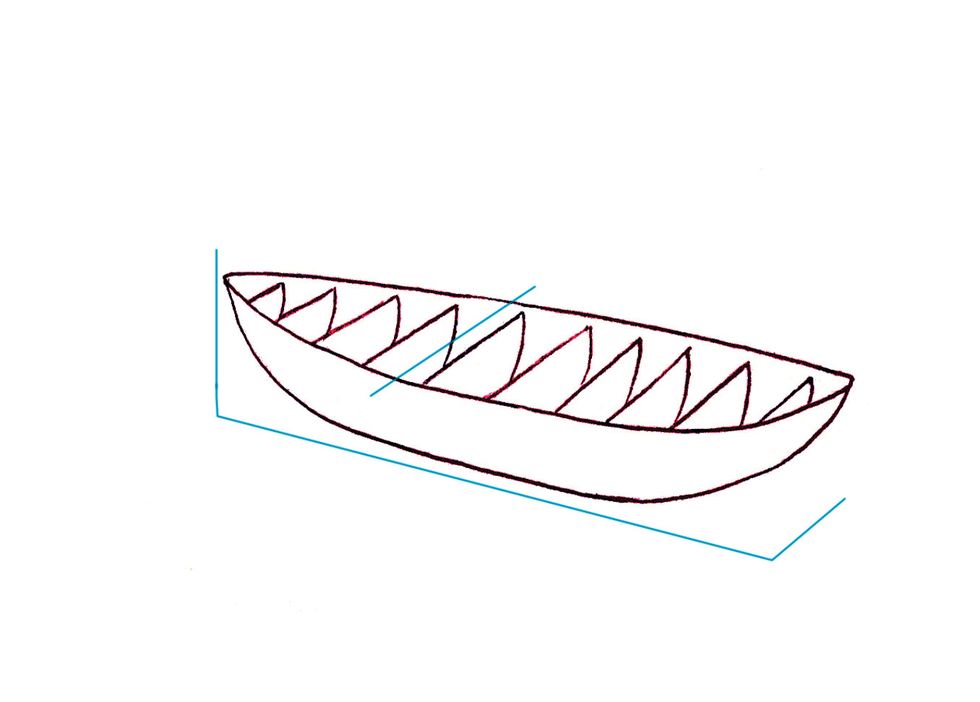

Step 1: Design a basic hull form or use an existing form on a CAD program.

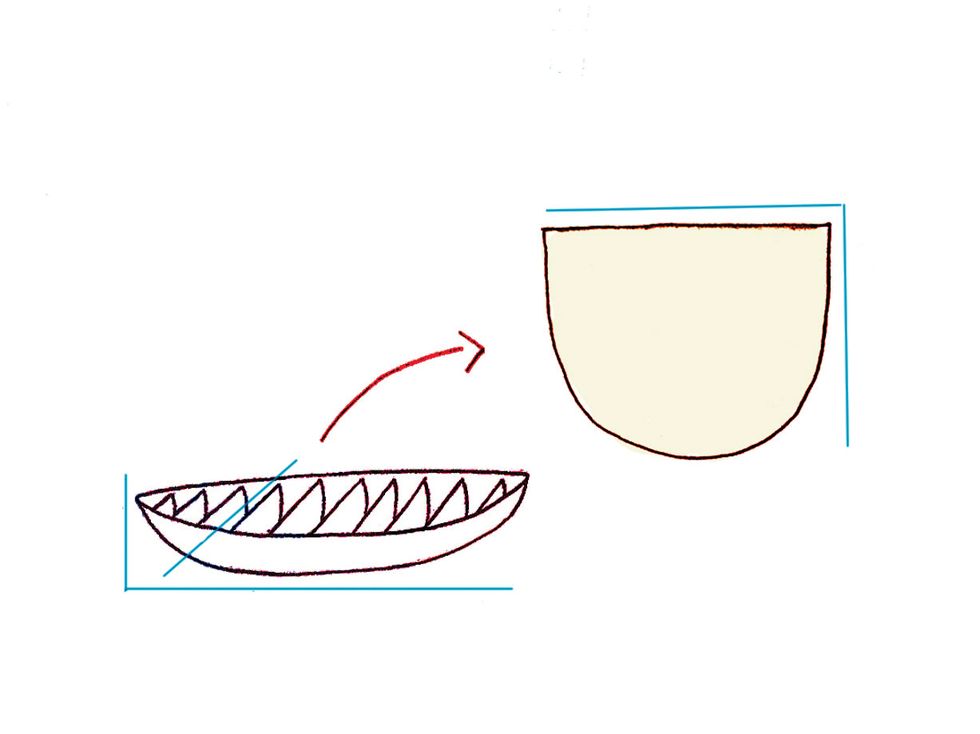

Step 2: Print cross sections of the hull at regular intervals onto paper templates. Transfer these templates to pieces of plywood.

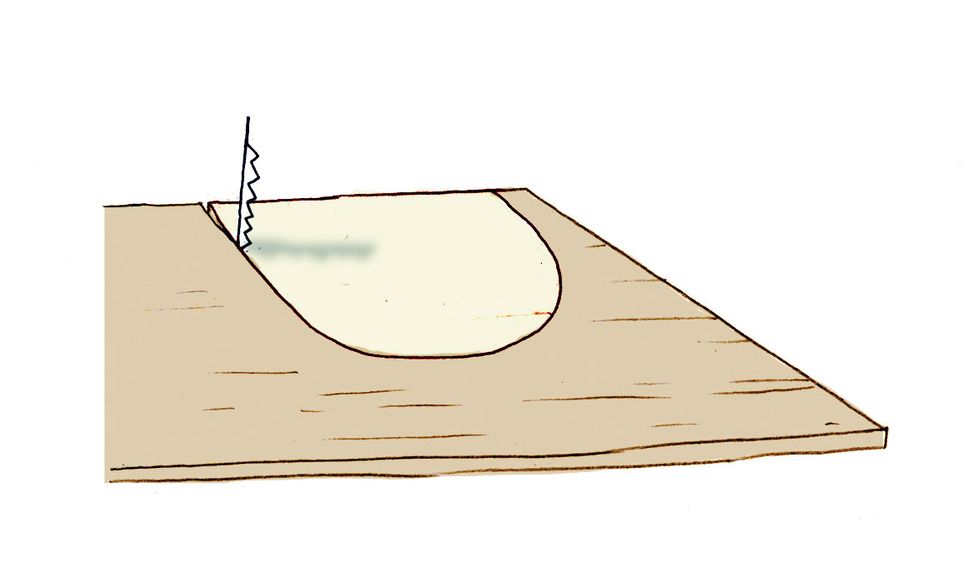

Step 3: Cut out the cross sections from the plywood using a jigsaw or a band saw.

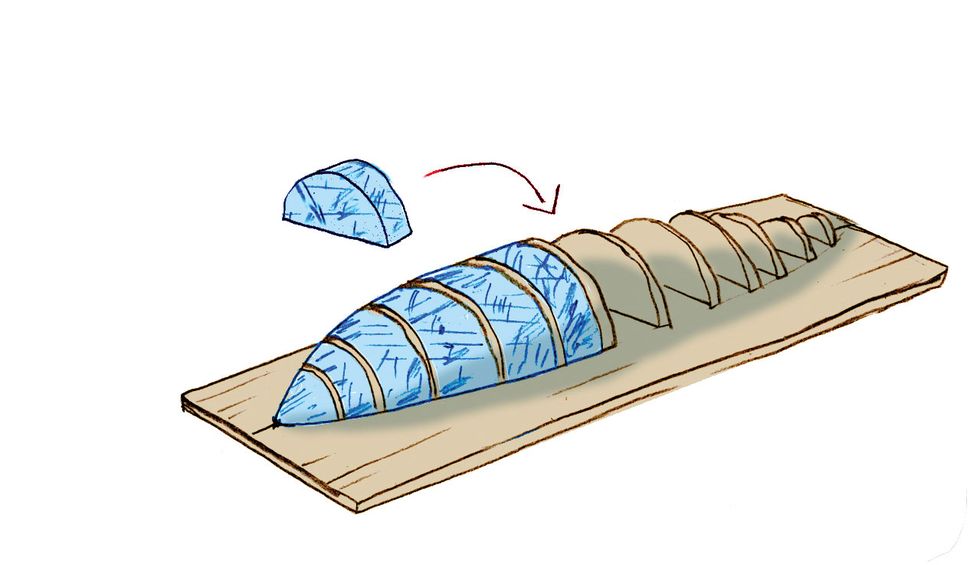

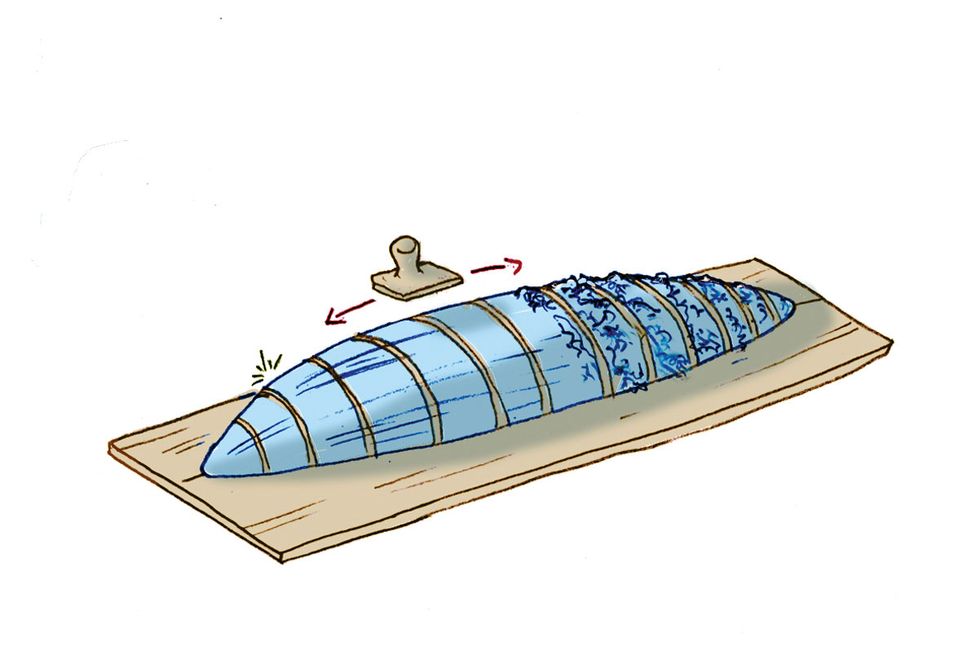

Step 4: Assemble the plywood pieces by standing them up—spaced according to the design—and fastening them to a rigid piece of lumber called a strong back. Insert pieces of rigid foam insulation in the gaps, then trim the excess using a knife or reciprocating saw.

Step 5: Sight down the hull form to locate any low areas in the foam or plywood. If you find any, build them out with drywall compound. Once any drywall compound is dry, sand the shape as smooth as possible. Apply water with a cloth to the hull form to reduce the concrete's tendency to bond to it.

Step 6: Mix the concrete and apply a ½- to 1-inch layer to the hull using trowels, floats, and your hands. The thicker the layer, the heavier the boat, but also the better the boat will tolerate stress.

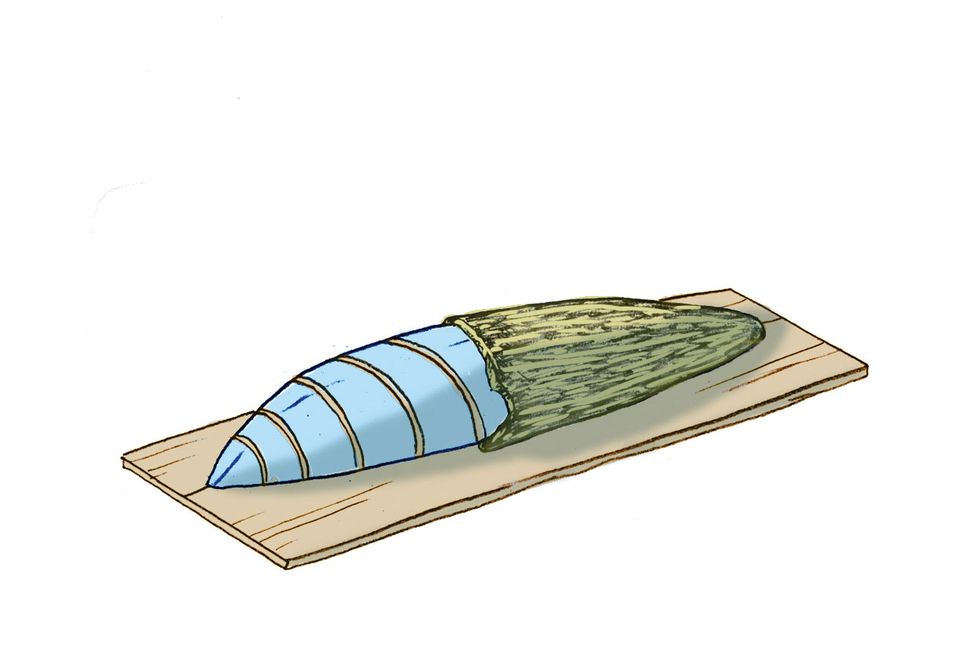

Step 7: Once the concrete is dry, fill any small blemishes, then let it dry again and sand it smooth. Once the smoothing is complete, carefully lift the hull from the mold.

This originally appeared in the September 2017 issue.