News

In a quest to make my 1982 Mercedes W123 run even smoother

I will say that at this point, my W123 was probably running better than 99% of the W123s worldwide, but that is simply not good enough for me.

BHPian Jeroen recently shared this with other enthusiasts.

On the W123, although the engine is running so much better than before it is still not 100% perfect. When it comes to my cars, I am completely anal. Everything has to be perfect. Nothing less will do, no matter what amount of time/money it takes.

So I decided to fiddle about with the ignition and carburettor some more. Earlier my friendly Alfa specialist Goos allowed me to use his CO analyser on my W123. Raised the CO a bit as that usually means smoother running on these old carburetted engines.

And it did improve the running. But still not 100% perfect. I will say that at this point my W123 was probably running better than 99% of the W123 worldwide, but that is simply not good enough for me.

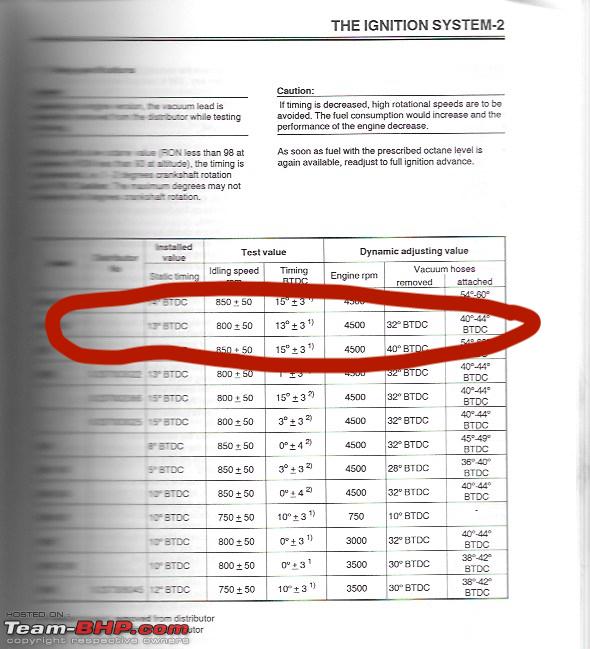

So decided to try a few other things as well. I went through all my W123 manuals again and visited a number of W123 forums around the world. Funnily enough, I get conflicting information with regard to how or even whether you can measure the ignition timing on my W123 with the electronic ignition. Some manuals and people claim you can only do this with the original W123 diagnostic equipment. My W123 friend Cor has it, but I did not want to bother him again.

So I had a go with my generic diagnostic tools. The thing I wanted to verify was the amount of static timing. According to my manual and also there is a little specification plate mounted under the bonnet, saying it should be around 13o +/- 3o.

I checked it with two different measurements. I used this old Ford diagnostic tool.

It measures various things, including RPM and the dwell angle. Dwell angle is not the same as static timing. Dwell angle is the angle of rotation that the ignition contacts are closed. Static timing is the angle at which the contacts close. But as this is an electronic ignition you can’t measure dwell with this tool. However, from what I can figure out it will actually measure static timing!

I also verified this with my strobe tool. Point it at the front pulley and read the number of degrees!

Sure enough both tools gave me the same value! Around 13o. I experimented with a bit more and a bit less. Took it for test drives. Ultimately I found at 15o the engine runs almost perfectly, let's say 99,7%. Good enough for now.

One thing though, you do need to disconnect the vacuum advance on the distributor. Initially, I had not bothered as I thought it would not make a big difference at idle. But it did, almost 3-4o!

Whilst I was fiddling with the engine I notice a wire hanging loose from the carburettor.

This is the wire from the electromagnetic stop valve at the bottom of the carburettor. The connector was still attached to the carburettor so I pulled it off.

Opened it up and the wire had just broken. It was soldered into the pin.

I must have knocked it off whilst I was adjusting the CO content which is done by turning the stop valve, but it does mean loosening up the locking nut with a big wrench size 22. Even so, it looks like this wire connection was a bit iffy to start with.

I drilled out the solder in the little hole. Made a simple set-up in the engine bay so I could solder it back on. The wire was pretty short so I had no other option.

The trick with soldering is to heat up the metal pin to the point where the solder melts. If you just touch the solder to the soldering gun, it will melt, but it will not be a good solid joint.

Everything back together again.

Two more little jobs

I fixed my broken nose-pliers. I broke them a few weeks ago while working on the Jeep.

I saw off the longer piece and then used my grinder wheel to get it sort of back into a half-decent shape. It will do, but I will buy a new one too! (As if I need a reason to buy more tools)

The last little job was on the hood of the Spider. As I have shown before the little plastic window has a tear in it. It happens to all of these, mine is well over 25 years old. Now, I do want my cars to be perfect. But this is actually one defect that doesn’t bother me really. Because I always drive top down anyway. And replacing the hood is not something I want to do myself. I know a guy that specialises in this kind of work. It will cost upwards of Euro 1500. So that is a lot of money. However, I have noticed Mrs D. doesn’t like it. So I am waiting for her to tell me to get it fixed properly. So she is responsible for this outlay!

Till then a bit of transparent tape will have to do!

Looking forward to Thursday when spanner mate Peter and I will be re-installing the steering box on the Spider.

Check out BHPian comments for more insights and information.

- Tags:

- Indian

- Member Content

- W123

- Mercedes

.jpg)

.png)